Differences between PE battery separator and other separators (1)

According to the different batteries, the requirements for the hydrophilic wettability of the separator are also different (eg: PE separator, PVC separator, PP separator, etc.) The wet-type charged battery requires that the separator of the battery has good re wettability, that is, after the first wetting, whether the separator is air dried or not, it is required to have another hydrophilic wettability.

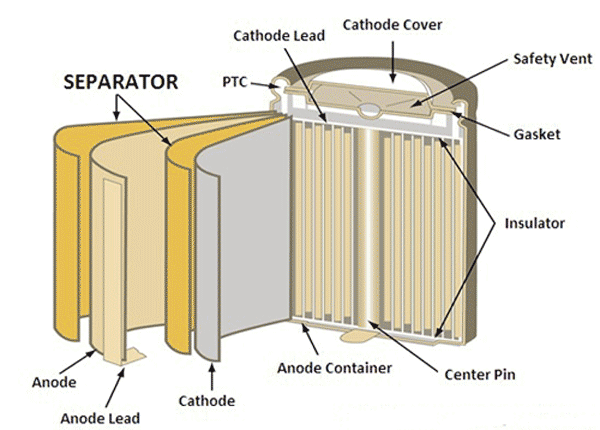

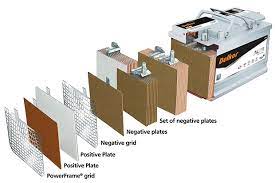

PE battery separator belongs to microporous polymer separator product series, which is mainly used for the isolation of cathode and anode in lead-acid battery electrolyte. Polyethylene partition has high oxidation resistance and puncture resistance, low ionic resistance, excellent flexibility and sealing.

The raw materials of the product are composed of ultra-high molecular polyethylene, amorphous silicon dioxide and special oil. The formula also contains carbon black and antioxidants. NN xylidine resin diaphragms are mostly treated with surfactants to give the diaphragms hydrophilic wettability. Due to the different selection of surfactants and treatment processes, the retention ability of diaphragms to surfactants is different. Some diaphragms have significantly decreased hydrophilic wettability again, while others maintain good hydrophilic wettability again.

The resistance of diaphragms with good re hydrophilic wettability remains stable, while the resistance of diaphragms with no re hydrophilic wettability or poor re hydrophilic wettability will increase; The hydrophilicity and wettability of the clapboard are declining, and the resistance of the clapboard will gradually increase, and the increase range varies with the raw materials used to make the clapboard.