PE+GM Battery Separator

Brand: JHTD

Product origin: China

Delivery time: 10 working days

Supply capacity: Sufficient capacity, can meet the needs of any well-known large customer

- PE+GM battery separator is a composite battery material specially engineered for extra heat and oxidation resistance as such, it may be termed as ‘Tropicalised Separator’ highly suited for high temperature abusive conditions.

- PE+GM battery separator with the unique glass fiber-polymer integration affords additional elements of plate protection and extended battery life.

PE+GM battery separator (sheet)

Introduction

Separators' Materials include nonwoven fibers (cotton, nylon, polyesters, glass), polymer films (polyethylene, polypropylene, poly (tetrafluoroethylene), ceramic and naturally occurring substances (rubber, asbestos, wood).

PE+GM battery separator would enhance the separator's oxidation resistance by separating the separator from the plate. The flat glass mat also will prevent the plate active material from shedding and extend the battery's life. Adapt to high vibration and deep discharge batteries, such as batteries for engineering machinery, cars and tractors.

Feature

PE+GM battery separator is a composite battery material specially engineered for extra heat and oxidation resistance as such, it may be termed as “Tropicalised Separator” highly suited for high temperature abusive conditions. The unique glass fiber -polymer integration affords additional elements of plate protection and extended battery life.

Overview

Quick Details

| Brand Name: JHTD | Size: General / Customized |

| Place of Origin: China | Porosity: ≥55% |

| Model Number: PE+GM battery separator | Moisture Content: ≤4.0% |

Type: Insulation Film, polyethylene separator | Dimension Stability: ≤1.0% |

Material: PE and fiberglass mat | Acid Weight Loss: ≤4.0% |

| Tensile Strength: 8N | Fe Content: ≤0.010% |

Usage: Automotive, Industrial | Cl Content: ≤0.030% |

Specification

TYPE | O/A Thickness (mm) | Width (mm) | Roll length (mm) | |||

PE | GM | PE+GM | ||||

ROLL | MOTOCYCLE | 0.8-1.2 | 0.3-0.8 | 1.1-2.0 | 116-126 | 500-800 |

0.8-1.2 | 0.3-0.8 | 1.1-2.0 | 150-170 | 500-800 | ||

AUTOMOTIVE | 0.6-0.9 | 0.3-0.8 | 0.9-1.7 | 500-200 | 500-800 | |

CUT PIECE/ ENVELOPE | TO MEET YOUR REQUIREMENT | |||||

No. | Item | Unit | Specification |

1 | O/A Thickness | mm | (0.9-2.0)±0.1 |

2 | Moisture Content | % | ≤4.0 |

3 | Wet-out Rate | Sec. | ≤30 |

4 | ER | Ω.dm2 | ≤0.0015 |

5 | Porosity | % | ≥55 |

6 | Acid Weight.Loss | % | ≤4.0 |

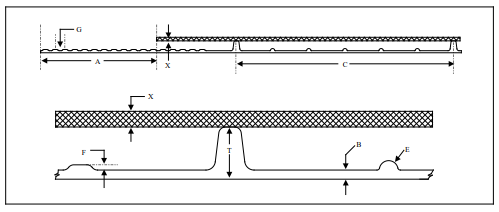

Nomenclature

Example:

135MM X 157MM X 1.2MM X 0.25MM X CUT PIECE

Thickness, width and length and type are according to the customer's request.

Separators are critical components in liquid electrolyte batteries. A separator generally consists of a polymeric membrane forming a microporous layer. It must be chemically and electrochemically stable with regard to the electrolyte and electrode materials and mechanically strong enough to withstand the high tension during battery construction. They are important to batteries because their structure and properties considerably affect the battery performance, including the batteries energy and power densities, cycle life, and safety.

FAQ

Q1: Is there back mini rib?

It depends on customer's requirement. For thickness more than 1.3 mm, there must be back mini rib.

Q2: What is the rib style of the separator?

We can communicate according to customer's drawing or picture of separator.